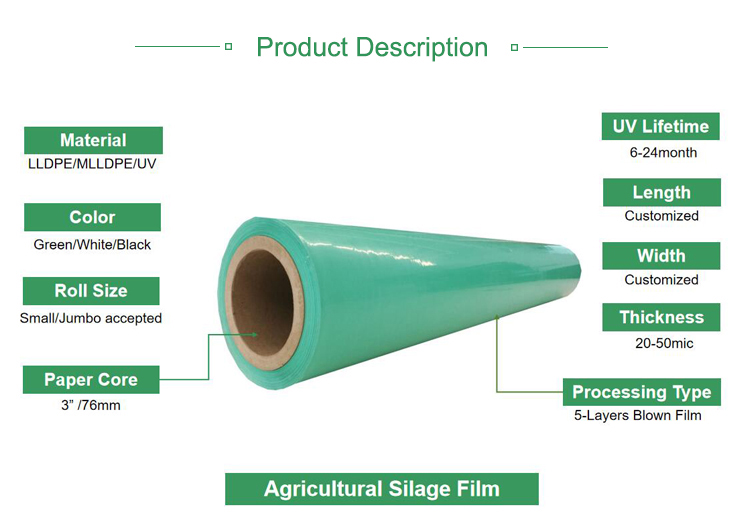

Silage Grow Bale Wrap

It is also named Bale Wrap. It is used for packing in baled products as animal feed. It maintains products healthy long time in the outside, thanks to UV resistance and low oxygen permeability.

Properties:

5 or7 layers co-extruded quality film

Superior strength

Resistance to tear and puncture

Ideal sticky for optimum fermentation

Additive of protective UV up to 1 year

Eco friendly, biodegradable 100%

Suitable for all types of bale wrap

Properties:

5 or7 layers co-extruded quality film

Superior strength

Resistance to tear and puncture

Ideal sticky for optimum fermentation

Additive of protective UV up to 1 year

Eco friendly, biodegradable 100%

Suitable for all types of bale wrap

Typical Range:

|

Width(mm) |

Length(m) |

Thickness(u) |

Core |

Color |

Packaging |

|

750 |

1500 |

25 |

3” Plastic |

White

Black

Green |

Carton pack in skid |

|

500 |

1800 |

25 |

|||

|

375 |

1500 |

25 |

|||

|

250 |

1800 |

25 |

Operating Instruction

Do not overstretch. The rate of stretch is advised:55-70%.

- The latter film later should cover 50% of the former stretch film, when the silage grass film is wrapped. After wrapped, the end of wrapped should be plugged into the layers of films. It is recommend to wrap 3-4 layers in total.

- After wrapped, if there is the obviously damaged on the surface, suggest to seal it with the suitable tape.

- The silage bales can not be transported by rolling and be away from the toxic chemicals.

- The silage bales should be stored away from the plants and livestock. If there is a damaged, it should be sealed with the suitable tape, immediately.

- When the silage is ready to use on the machine, it should be double check if there is any a little tiny damaged. Otherwise, it may lead to the film breaking.

The silage grass film, which is not used up should be stored in cool and dark condition and is protected from moisture and surface damaged

Technical Data Sheet

|

Property |

Units |

+/- |

Data |

Test Method |

|

|

Thickness |

|

um |

1.5 |

25 |

|

|

Tensile Strength

|

MD |

Mpa |

3 |

42 |

ASTMD882 |

|

TD |

35 |

ASTMD882 |

|||

|

Elongation At Break |

MD |

% |

5 |

480 |

ASTMD882 |

|

TD |

620 |

ASTMD882 |

|||

|

Elmendore Tear |

MD |

gm |

5 |

610 |

ASTMD1922 |

|

TD |

850 |

ASTMD1922 |

|||

|

Dart Impact |

|

gm |

5 |

235 |

ASTMD1709 |

|

Puncture Resistance |

|

N/um |

10 |

490 |

Exxon Mobile Method |

|

Stickiness |

|

N/10cm2 |

0.5 |

7.50 |

BEN-516 |

|

Prestretch |

|

% |

10 |

180 |

|

|

UV Protect: guarantee 12 months |

|||||